Why Does EDPMS work at High Wellbore Deviation?

posted on 06 February 2023 4:13 PM by DataWise

• The EDPMS concept works on the basis of a low density gas staying above heavier wellbore fluid within a closed column to surface.

• A bottom hole fluid chamber is critical to an effective EDPMS system in order to accommodate the normal pressure variations of the well and still maintain accuracy.

• Chamber volumes of an effectively designed system will enable 90% or greater of system gas to be maintained near the fluid interface, which means in the chamber.

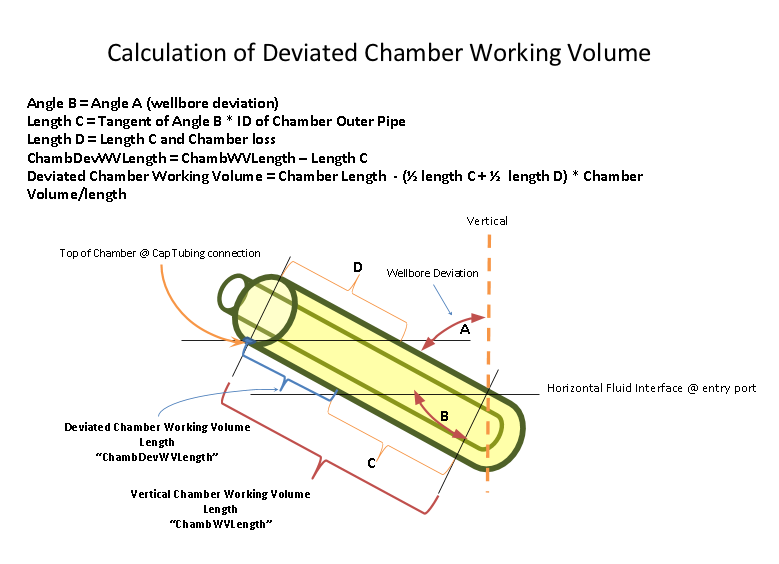

• Changing the chamber angle due to wellbore deviation will only change the angle of the wellbore fluid, EDPMS gas interface.

• Since the EDPMS is a closed end system there is no fluid flow, so coning does not occur, insuring chamber volume acts as designed.

• The EDPMS chamber is designed based on the required installation configuration, and therefore wellbore deviation of the chamber is considered in the design.

• Chamber length can be increased and chamber ID can be decreased (if possible) to allow an EDPMS system to work at high angles.

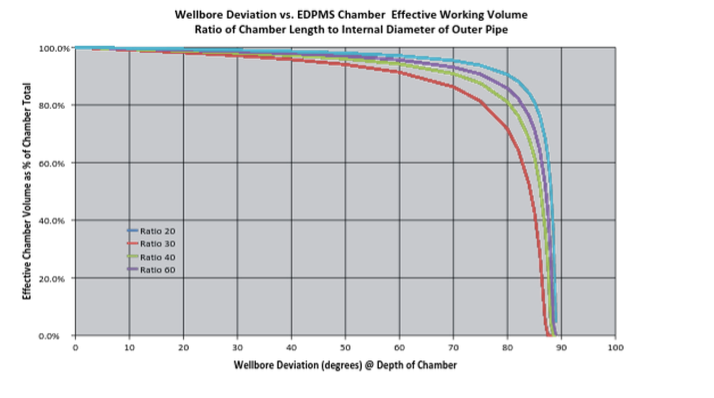

• Based on the ratio of Chamber ID (outer pipe) to Chamber length (working volume)standard of 20 – 60 to 1, chamber working volume decreases little until approaching 80 degrees deviation.

• A bottom hole fluid chamber is critical to an effective EDPMS system in order to accommodate the normal pressure variations of the well and still maintain accuracy.

• Chamber volumes of an effectively designed system will enable 90% or greater of system gas to be maintained near the fluid interface, which means in the chamber.

• Changing the chamber angle due to wellbore deviation will only change the angle of the wellbore fluid, EDPMS gas interface.

• Since the EDPMS is a closed end system there is no fluid flow, so coning does not occur, insuring chamber volume acts as designed.

• The EDPMS chamber is designed based on the required installation configuration, and therefore wellbore deviation of the chamber is considered in the design.

• Chamber length can be increased and chamber ID can be decreased (if possible) to allow an EDPMS system to work at high angles.

• Based on the ratio of Chamber ID (outer pipe) to Chamber length (working volume)standard of 20 – 60 to 1, chamber working volume decreases little until approaching 80 degrees deviation.